High voltage coolant heating delivering efficient thermal management for battery and cabin heating in electric and hybrid vehicles

MicroHeat has patented Direct Energy Transfer (DET) fluid/glycol/water heating technology for automotive high voltage coolant heating in thermal management coolant circuits, targeted at electric and hybrid vehicles.

MicroHeat high voltage coolant heating technology can be readily applied to an existing automotive coolant heating system to provide faster, more accurate and more efficient coolant heating for electric vehicles and hybrid vehicles. Our Australia made coolant heaters are superior to what is available today, particularly in cold climates.

How it Works

The MicroHeat coolant heater technology adapts dynamically to the vehicle’s changing conditions, whether it be to adjust to flow changes, ramp up and stop heating, accommodate conductivity changes within the coolant or simply change the temperature in the circuit. Our hybrid and electric vehicle coolant heater does this better and faster than any other coolant heater for cars on the market.

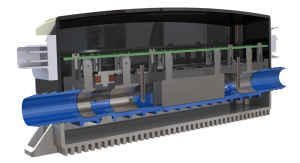

The system connects within the coolant circuit to deliver coolant heat for cabin heating heat exchange and coolant heat for the batteries, whether running or charging, as well as electronics and drives during cold climate conditions – wherever heat boosting is required across the vehicle.

The car coolant heater unit can be fully integrated into the vehicle management system, where bi-functional control can be delivered between the coolant system and the vehicle. The unit senses changes in coolant conductivity and varies the power to the coolant to enable the most efficient heat transfer and ensure the highest thermal transfer efficiencies are achieved at all times.

Our electric and hybrid vehicle coolant heater systems can perform on their own either as a central coolant heating source or at the point of use around the vehicle, reducing coolant line runs and coolant volume and ensuring the most optimised energy transfer solution to enable the vehicle to go further. The unit can also be used as a booster for fast charging or as a standby booster for heat pump solutions, either as pre-booster or post booster to the existing heat pump solution.

MicroHeat engine coolant heater technology offers advantages to existing technologies, including size, weight reduction, coolant volume reduction and optimised heating energy usage that conserves battery life, combined with accurate and responsive heating temperature control and design flexibility (plastic and low-pressure capability). These advantages are provided without the inherent traditional electric sheathed/bare element heating failures, such as unresponsive and inaccurate temperature control, burn out, thermal inertia and stress corrosion.

We are actively working with automotive OEMs and seeking development partners to co-develop our made in Australia car coolant heaters in OEM vehicles across the globe.

Enquire About Automotive Fluid Heating Today

If your organisation is interested in exploring this opportunity, please contact us using our contact us e-form to learn more about our automotive coolant heater systems.